Why Is My Pool Pump Making a Loud Noise? (Diagnosis & Easy Fixes)

Stop the noise! Diagnose why your pool pump is loud. We cover worn bearings, cavitation, and debris jams with simple step-by-step repair tips.

A sudden screech or grinding rumble from your pool equipment can turn a relaxing afternoon into a stress spiral. When you are wondering why is my pool pump making a loud noise, you are not alone—and the sound is rarely random. Most pool pumps run at 60 to 85 decibels under normal load, roughly the volume of a vacuum cleaner. When bearings seize or cavitation starts, that volume spikes sharply and signals real mechanical distress.

The good news is that your pump is communicating directly with you. Each sound pattern acts as a diagnostic code. A high-pitched whine points to worn bearings. A gravel-like grind suggests air starvation or debris trapped in the impeller. A low hum often means an electrical start failure. Before you touch any bolts or open the strainer basket, shut off power at the breaker.

Water and electricity do not mix, and a moving impeller can cause serious injury. Once the power is off, you can translate those noises into specific fixes and avoid costly guesswork.

Screeching or Whining? How to Check for Worn Bearings

A high-pitched metallic scream usually means the motor bearings have lost their lubrication. These steel rings allow the rotor to spin smoothly inside the motor housing. After roughly 5 to 7 years of outdoor heat, chlorine vapor, and rain exposure, the grease breaks down and rust forms. The result is metal grinding against metal at 3,450 rotations per minute, producing that signature screech.

The cause

Bearings fail from age, water intrusion through a failed shaft seal, or simply running the pump dry during a leak. Once the protective grease washes away, the bearing races develop flat spots. The noise typically starts intermittent and grows constant within days.

Rear motor test

Place the plastic end of a screwdriver against the back center of the motor housing and press your ear to the handle—this acts as a stethoscope. If the screeching is loudest at the rear, the rear bearing is failing. If the noise echoes from the front by the impeller, the front bearing is the culprit. Do not perform this test while the pump is running if the housing is wet.

Fix options

You have two paths. A pool technician can press out the old bearings and press in new ones, which costs $150–$300 in labor plus parts. However, if the motor is over eight years old or shows signs of overheating, replacing the entire motor or pump assembly is often smarter. New bearings in a tired motor may only buy you another season before the windings fail.

Grinding or “Gravel” Sounds? Diagnosing Cavitation

Cavitation sounds like rocks tumbling inside the pump basket. It happens when the impeller starves for water and begins churning air bubbles instead. Those bubbles collapse violently against the impeller blades, creating the grinding noise and physically pitting the metal or plastic within weeks.

Air bubble check

Shut off the pump and open the strainer lid. If the basket is only half full of water or filled with foamy air bubbles, the pump is pulling in air from a leak on the suction side. Common leak points include the pump lid O-ring, threaded fittings into the pump, or cracks in the underground plumbing. For a systematic method to locate these leaks, refer to this guide on How to Find a Pool Leak and Fix It.

Water level

The skimmer opening must sit halfway submerged. If the pool water drops below the mid-tile line, the skimmer gulps air directly into the suction line. Maintain water level at least halfway up the skimmer mouth to prevent vortexing.

Impeller clearance

With power locked out, reach into the pump basket and feel the impeller blades through the suction port. Remove any lodged pebbles, leaves, or plastic shards. Spin the impeller by hand—it should rotate freely with a gentle magnetic resistance. If it grinds or wobbles, the impeller shaft is bent and requires replacement.

Rattling or Shaking? Stabilizing the Mount

Vibration noise travels through concrete pads and plumbing like a tuning fork. A pump that rattles against its base creates a drumming sound that seems louder than the motor itself. This often starts after freeze-thaw cycles shift the equipment pad or after years of torque loosen the anchor bolts.

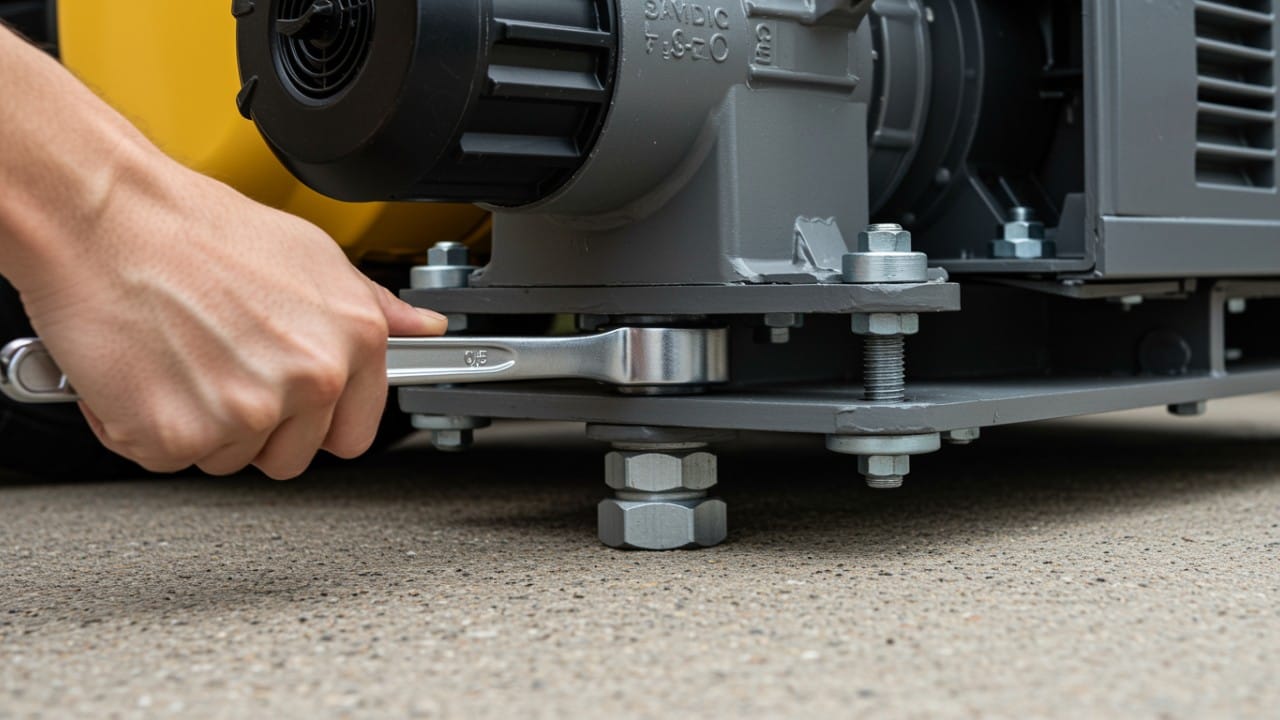

Bolt tightness

Place your hand on the motor housing while it runs. If the noise dampens when you press down, the pump is rocking. Tighten the four base bolts that secure the motor to the seal plate and the pump body to the pad. Use a wrench, not a screwdriver, to ensure 20–25 ft-lbs of torque. Do not overtighten, as this can crack the plastic housing.

Pad leveling

Slide a rubber isolation pad or anti-vibration mat under the pump base. These ¼-inch thick mats absorb harmonic vibration and can drop perceived noise by 5–10 decibels. Ensure the pad sits level; a tilted pump strains the shaft seal and creates new leaks.

Humming or Buzzing? Capacitor and Jam Issues

A loud electrical hum followed by silence—or a hot motor that refuses to start—points to a failed start capacitor or a seized shaft. The capacitor stores the electrical charge needed to jolt the motor from standstill to full speed. When it dies, the motor hums against locked rotor amps and risks burning out within minutes.

Impeller jam

Turn off the breaker and attempt to spin the motor shaft through the rear ventilation slots using a flathead screwdriver. If the shaft will not budge, debris has jammed the impeller. Disassemble the pump housing to clear the obstruction before testing again.

Capacitor test

Locate the metal hump on the side of the motor housing—the capacitor sits inside. Discharge it safely with an insulated screwdriver across the terminals before handling. If the capacitor top is bulged or leaking oil, it has failed. Match the microfarad (µF) and voltage ratings exactly when ordering a replacement, or hire a technician. Capacitors retain lethal voltage even when the power is off.

Repair or Replace: Making the Smart Financial Choice

Deciding whether to rebuild or retire a noisy pump comes down to math and mechanical risk. A single-speed pump manufactured before 2021 may also face Department of Energy efficiency mandates that make replacement economically attractive regardless of the repair cost.

The 50% rule

Industry guidance from pool service associations suggests the 50% threshold: if the repair quote exceeds half the price of a new pump—including installation—replacement is the better investment. A new single-speed pump runs $400–$800 installed, while variable-speed models range $1,200–$1,800. Factor in that modern variable-speed pumps operate at significantly lower RPMs for daily filtration, producing roughly 20–30 decibels less noise than single-speed units at full throttle. For detailed current pricing, see this Pool Pump Costs Revealed.

Reduce system strain

You can extend any pump’s life by reducing its daily workload. Running a robotic cleaner independently from your filtration system captures debris before it reaches the skimmer, allowing you to run the main pump fewer hours per day. This reduces bearing wear and energy consumption. Learn more about filtration alternatives in this comparison of Robotic vs. Suction Pool Cleaners.

Failure signs

Some noises signal imminent catastrophic failure. If the pump housing leaks water onto the motor, if the motor housing exceeds 180°F (too hot to touch), or if the breaker trips repeatedly, the pump poses a fire risk. Review the 8 Key Signs You Need to Replace Your Swimming Pool Pump to verify whether your unit has reached end-of-life.

How Aiper Helps You Bring Vacation Home (With Less Pump Noise)

Your backyard should sound like water lapping against tile, not machinery grinding through a maintenance cycle. When you reduce the burden on your main filtration pump, you reduce the noise pollution that comes with it.

Aiper robotic cleaners operate independently from your pool’s plumbing, which changes how your equipment pad behaves:

- Independent debris removal: The Aiper Scuba X1 Pro Max captures leaves and sediment directly into its internal filter, bypassing the skimmer and reducing the load on your main pump.

- Shorter filtration cycles: Because the robot handles surface and floor debris, you can run your main pump 30–50% less daily, cutting down on bearing wear and electrical hum.

- Cordless quiet operation: No booster pumps, no suction hoses, no whining pool-side vacuums—just the low whir of the robot’s DC motor as it climbs walls.

- Waterline care: By scrubbing the tile line where oils concentrate, the robot prevents the surface film that often forces pumps to work harder against clogged skimmers.

- Consistent cleanliness: Regular robotic cleaning prevents algae blooms that demand aggressive shock treatments and extended pump runtime to clear.

FAQs About Pool Pump Noise

What exactly is cavitation and why does it sound like rocks?

Cavitation occurs when the pump impeller spins faster than water can flow into it, creating low-pressure zones where water vaporizes into bubbles. Those bubbles immediately collapse against the impeller blades with explosive force, producing the grinding noise. It sounds like gravel because thousands of microscopic bubble collapses per second create rapid mechanical impact.

How do I know if my bearings are worn out?

The sound is distinctly metallic and high-pitched, like a squealing car brake. You may also notice water leaking from the shaft seal directly below the motor, which indicates the seal has failed and likely contaminated the front bearing with pool water.

How do I remove debris stuck in the impeller?

Turn off the power at the breaker. Remove the pump basket and reach through the suction port with needle-nose pliers to extract leaves or twigs. If debris is wedged behind the impeller, remove the four bolts holding the motor to the seal plate, slide the motor back, and clear the blockage manually.

Why is my pump vibrating against the equipment pad?

Loose anchor bolts, a cracked concrete pad, or missing vibration dampeners allow the pump to rock. Tighten all base bolts to manufacturer torque specs and install a rubber isolation pad. Check that the PVC plumbing does not pull or twist the pump housing, which transfers pipe vibration into the pad.

What to do if a pool pump is making a loud noise?

Shut off power immediately to prevent motor burnout or fire. Identify the specific sound—screeching, grinding, humming, or rattling. Check for visible issues like low water levels or loose bolts. If the cause is not immediately obvious, call a technician before restarting the pump.

What noise does a water pump make when it’s going out?

A failing pump typically progresses from intermittent screeching (bearings) to constant grinding (cavitation or impeller damage) to a final loud hum followed by silence (seized motor or tripped thermal overload). Once the motor hums but does not spin, the windings are likely damaged beyond economical repair.

What is the most common cause of a noisy circulating pump?

Worn bearings from age and cavitation from suction-side air leaks account for roughly 80% of pump noise complaints. Bearings fail from natural lubricant breakdown, while cavitation stems from water levels dropping below the skimmer or leaks in the plumbing drawing in air.

What are the signs of a pool pump failing?

Excessive noise is the primary audible indicator. Visual cues include water leaking from the seal plate, rust streaks under the motor, and discoloration from overheating. Operational red flags include the pump failing to prime, tripping the electrical breaker, or the motor housing reaching temperatures above 140°F.

Can I run my pool pump if it’s making a loud noise?

Generally, no. Screeching bearings generate heat that can melt the motor windings. Cavitation causes physical impeller damage that shards plastic into your filtration system. A seized motor drawing locked rotor amps creates a fire hazard. Run the pump only long enough to identify the noise source, then power down.

How long do pool pump motors usually last?

According to pool industry data, residential pump motors average 8 to 12 years in temperate climates. Units in hot, humid regions with direct sun exposure often fail closer to the 6–8 year mark due to thermal stress and seal degradation.

Conclusion

A noisy pump is not just an annoyance—it is your equipment asking for help. By matching the specific sound to its mechanical cause, you avoid the trial-and-error approach that wastes money on unnecessary parts. Whether you tighten a bolt, clear a jam, or decide it is time to upgrade to a quieter variable-speed motor, the goal remains the same: reclaiming the peace of your backyard.

Reducing the workload on your filtration system extends its life and lowers the volume of your maintenance routine. When your pool care runs quietly in the background, you get back to what matters—actually enjoying the water.